With its brands, innovations, and technologies, Henkel holds leading market positions worldwide in the industrial and consumer businesses. Henkel Adhesive Technologies is the global leader in the adhesives, sealants, and functional coatings market.

Amongst the broad material portfolio, Adhesive Technologies has developed a large material portfolio of conductive inks and coatings suitable for printed electronics technology. Today, a global Printed Electronics Team manages the development of printed electronics applications with a cross-industry focus on market trends by building on more than four decades of market and material formulation expertise with strong partners that enable scalable solutions.

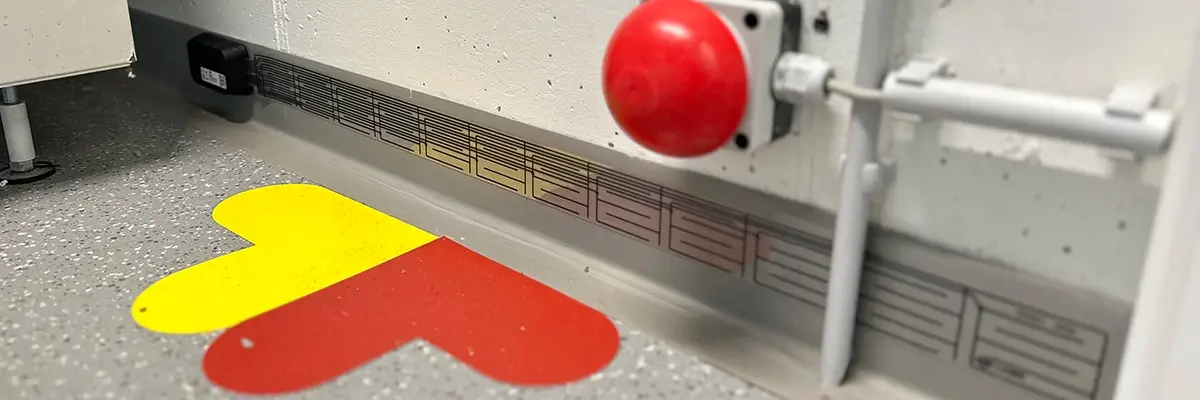

The company’s LOCTITE® functional ink and coatings portfolio is ideal for producing the next generation of flexible sensor solutions by accelerating the go-to-market of smart, seamlessly connected and data-generating product innovations. LOCTITE® inks and functional coatings for printed electronics allow customers – including LAIIER – to create thin, flexible, lightweight, and high-quality electronic solutions printable at high speeds.